Sheet + Plate

Cut and delivered on time to keep your business running strong.

Select Options

Stainless 304, also known as 18-8 stainless, is the most common steel used in a variety of uses because of the ease in which it can be formed into various shapes. Non-magnetic and highly resistant to corrosion makes it a good all-purpose stainless.

Type 316, also known as marine grade or surgical stainless steel, is particularly suitable for applications involving severe corrosive conditions, particularly pitting. Stainless 316/316L maintains strength, durability and workability and is ideal for lasting structural support in corrosive environments with harsh chemicals like salt water, acidic chemicals.

Stainless Steel 416 is a corrosion resistant chromium steel alloy that is non-seizing, non-galling, free machining metal widely used in automatic screw machines. Its short brittle chips make it ideal for increased machining speeds, larger cuts, and longer tool life.

Type 420 stainless steel is a general purpose steel and possesses similar qualities to the 410 grade, but contains more carbon which provides improved hardness and strength when heat treated. 420 stainless has good mechanical and machining properties.

Of the 400 series of stainless steels, 400C has the highest carbon content and moderate corrosion resistance and can heat-treat to the highest harness of RC 60. (In contrast, 416 is normally heat treated to RC 26/32)

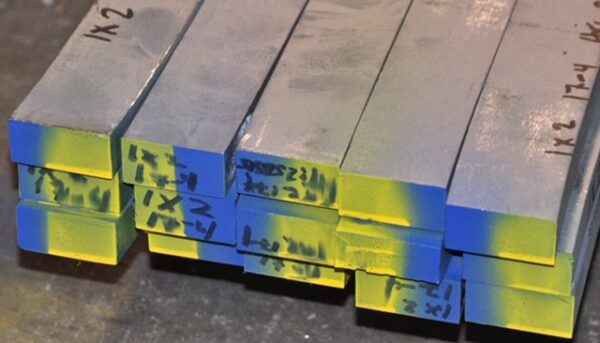

17-4, also known as 630 stainless, can be heat treated to high levels of strength and hardness, and good for machining and is corrosion resistant. Often used in petroleum and chemical industries, as well as in aircraft parts.

13-8 is a precipitation-hardening stainless steel that has excellent strength, high hardness, superior toughness, and good corrosion resistance. In addition, the alloy exhibits good ductility and toughness in large sections in both the longitudinal and transverse directions. Good transverse toughness properties are achieved by tight chemical composition control, low carbon content, and vacuum melting.

15-5 is a martensitic precipitation-hardening stainless steel that provides high strength, good corrosion resistance, good mechanical properties at temperatures up to 600°F (316°C) and good toughness in both the longitudinal and transverse directions in both base metal and welds. Alloy 15-5 is the ferrite-free version of Type 17-4 stainless steel. Both alloys are widely used […]

17-7 stainless steel is a stable, chromium-nickel-aluminum precipitation hardened stainless steel that provides high strength and hardness, excellent fatigue properties, moderately resistant to corrosion, good formability, and minimum distortion upon heat treatment.

This grade is a high nitrogen and molybdenum bearing austenitic stainless steel that has a comparable or surpassing corrosion resistance to that of 316/316L and 317/317L plus approximately twice the yield strength at room temperature. The alloy does not become magnetic when cold worked, unlike many austenitic stainless steels.

Nitronic® 60 Stainless Steel is best known for its fretting, wear and galling resistance in the annealed condition by the addition of silicon and manganese. Chromium and Nickel additions give it comparable corrosion to 304 and 316 stainless steels, while having approximately twice the yield strength. Additionally, this grade provides excellent high-temperature oxidation resistance and […]

This alloy is a nitrogen strengthened austenitic stainless steel that has excellent resistance to corrosion at high temperatures and provides remarkably good properties at elevated temperatures. Nitronic® 40 is about twice the yield strength at room temperature as that of 304, 321, and 347.