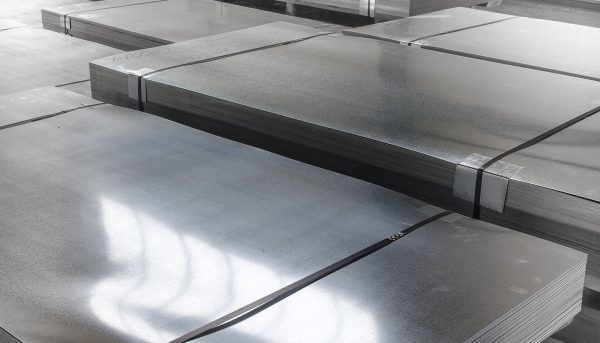

Metal and Plastic Products

Cut and delivered on time to keep your business running strong.

Select Options

Steel Grade E-4130 is also known as Chromoly Steel has approximately 0.30% carbon by weight. This alloy contains chromium and molybdenum to help give strength and corrosion resistance. Chromium helps to increase the hardenability and corrosion resistance and the molybdenum helps to increase toughness.

4140 is an alloy steel that is supplied in either annealed or prehardened condition. The chromium content provides good hardness penetration, and the molybdenum imparts uniformity of hardness and high strength. It is characterized by its high fatigue strength, torsional strength, abrasion resistance, toughness.

Alloy E-4330 is a high-strength alloy steel containing chromium, nickel and molybdenum with a carbon content in the range of 0.30% range. It is heat treatable and offers good formability and machinability with exceptional cold working characteristics.

Alloy E 4340 steel is a medium carbon, low alloy steel know for its toughness and strength. It is often used in deep-hardening construction steel. 4340 has good ductility in the annealed condition that permits it to be bent or formed. The high fatigue strength makes E4340 suitable for highly stress parts since it maintains […]

E-4620 steel in a nickel molybdenum alloy that is a carburizing steel producing a high case hardness and core toughness.

A high carbon, chromium electric-furnace processed alloy, 52100 is primarily a bearing steel possessing a high resistance to wear and abrasion. It also is a moderately deep hardening alloy with low softening resistance to elevated temperatures.

Alloy E 6150 is a medium carbon, chrome-vanadium, highly abrasion resistant, fine grain, killed alloy steel. When heat-treated, the material has excellent toughness and very good shock resistance making 6150 a good alloy for parts open to stress, shock, and vibration.

An electric-furnace processed, E-8740 is a Nickel Chrome Molybdenum alloy produced for case hardening. It is a very tough alloy, with excellent shock resistance and especially free from temper brittleness.

E-9310 is vacuum degassed, carburizing steel containing chromium, nickel, and molybdenum. It has a high hardenability, high core hardness together with high fatigue strength. 9310 offers excellent ductility and toughness.

Magnesium alloys are easy to machine and are very lightweight. When magnesium is alloyed with other metals such as aluminum, zinc, silicon, and iron, magnesium alloys are derived. Magnesium AZ31B-F alloy is a medium strength alloy.

Magnesium is a silvery-white metal which is used as an alloy element for zinc, lead, aluminum, and other nonferrous alloys.

Magnesium AZ61A-F alloy is available in forged, extruded hollow shapes and extruded solid shapes. This alloy is relatively inexpensive and exhibits good strength.