Metal and Plastic Products

Cut and delivered on time to keep your business running strong.

Select Options

110 Copper has the highest electrical conductivity of all copper alloys as well as corrosion resistant, takes very well to soldering and has the capacity to be stretched into a thin wire without becoming weaker or more brittle in the process.

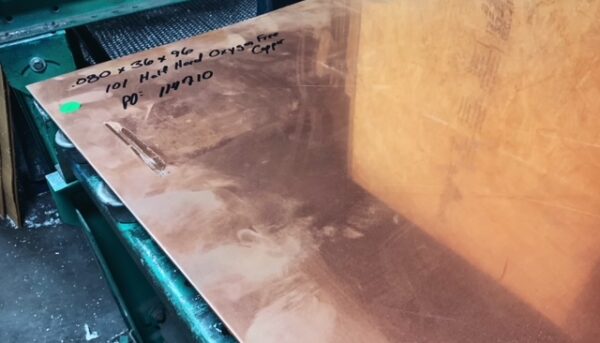

Copper alloy 101 is the designation for moderate copper used in engineering applications. High ductility and impact strength also serve to make an extremely useful material. Copper alloy C101 is the base material that common brasses and bronzes are produced from. 101 copper is 99.99% pure, and C102 copper is 99.95% pure, contain essentially no […]

This copper alloy has good hardness and electrical conductivity through a combination of cold working and heat treating. 182 Chromium is a class 2 copper and is suitable for resistance spot, flash, butt, projection and seam welding.

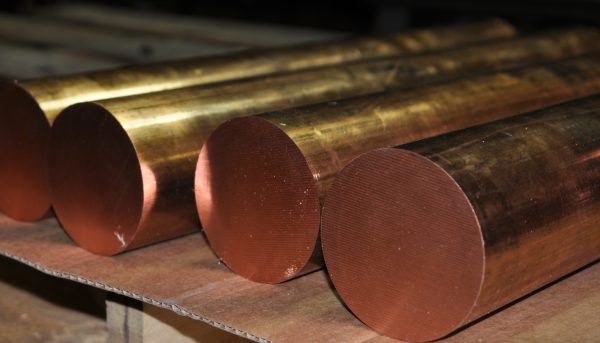

175 Beryllium copper is a bearing copper-base alloy which combines high strength with non-magnetic and non-sparking qualities. It has excellent metalworking forming and machining properties. It has many specialized applications in tools for hazardous environments, musical instruments, precision measurement devices, bullets, and aerospace.

Beryllium Copper 172 is commonly used in coal, oil, gasoline, natural gas, and aerospace components. Because of its non-magnetic, non-sparking attributes where sparks can be deadly in such hazardous environments.