Metal and Plastic Products

Cut and delivered on time to keep your business running strong.

Select Options

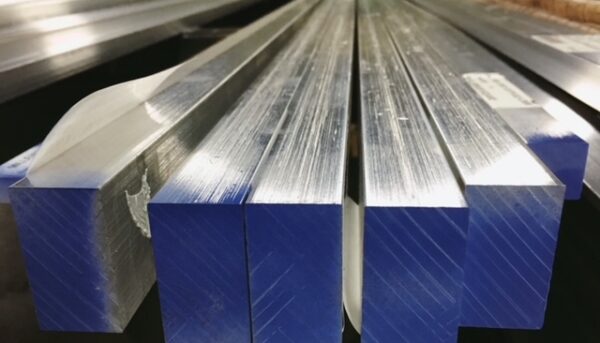

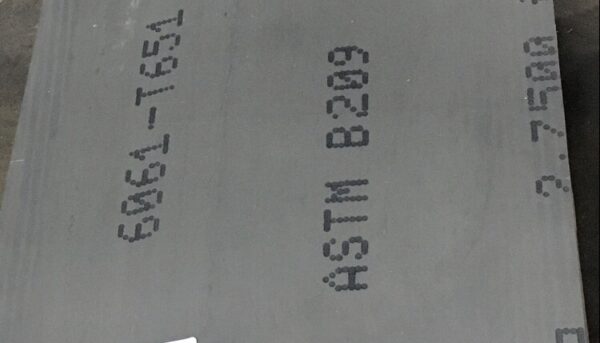

6061-T6511 is a screw machine alloy that has superior corrosion resistance and anodizing features and is one of the most commonly used aluminum alloys due to its numerous characteristics. It is generally selected where welding or brazing is to be performed and is also used extensively in forging applications.

All rounds are extruded 6061 T6 produced to ASTM B 221. Remember all online pricing is for smaller cut length items and prices include two free cuts and packing. For multiple full lengths please call 800-704-2157 for prices. Click on any item below to continue shopping. 6061-T6511 Extruded Aluminum Round Rod is frequently found in […]

6061-T6511 is a screw machine alloy that has superior corrosion resistance and anodizing features and is one of the most commonly used aluminum alloys due to its numerous characteristics. It is generally selected where welding or brazing is to be performed and is also used extensively in forging applications.

6061-T6511 is a screw machine alloy that has superior corrosion resistance and anodizing features and is one of the most commonly used aluminum alloys due to its numerous characteristics. It is generally selected where welding or brazing is to be performed and is also used extensively in forging applications.

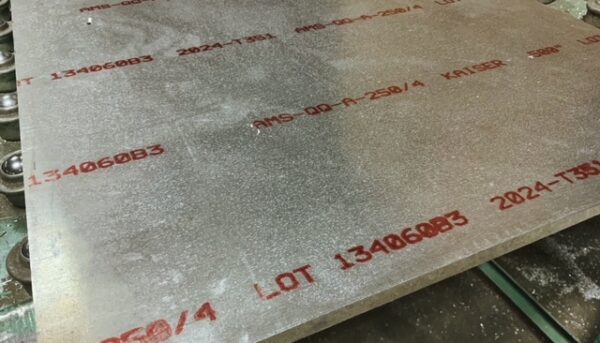

Popularly known as “the aircraft alloy”, 2024 has higher properties than 2011 or 2017 an is largely used for aircraft fittings. It is widely used for all types of threaded fasteners because of its relatively higher shear strength.

7075 is an aluminum alloy, with zinc as the primary alloying element. It is one of the strongest aluminum alloys comparable to many steels, and has good fatigue strength and average machinability. 7075 was specifically designed for aircraft frames because of its strength somewhat greater than steel while maintaining the light weight of aluminum.

Aluminum Cast Plate MIC-6 is a blend of the most desirable features of many individual metals and is known for its stability and consistency between plates. Because of its cast granular structure and stress relieving properties, it has superior flatness and dimensional tolerances on the thickness which makes it popular for tooling and base plates.

At 99% min aluminum, Aluminum 1100 is just one of several common aluminum alloys and is soft, low strength, is the commercially pure aluminum. It cannot be hardened by heat treatment and is very formable. 1100 is one of the widest used alloys, with excellent forming properties in annealed states and may be suitable for […]

Aluminum 2219 is an age-hardenable copper containing alloy of aluminum.

This alloy is 20% stronger than 1100 because manganese has been added and has good strength and is light weight. 3003 aluminum is well-suited to outdoor and harsh environment applications due to its durability and corrosion resistance. It has excellent workability and is used for spinning and stamping applications.